No. 11 of Eastern Outer Ring of Jiaozhou city, Qingdao,Shandong,China.

+86 18661790163 / +86 13220873371

Jane Liu

Introduction

One Step Insulation Pipe Machine-HDPE Polyurethane Pre Insulated Pipe Production Line

There’s one step and two step foaming process:

One step pre insulated production line consist of:

Pipe in platform-Pusher-Low pressure foaming machine-Extruder-Die head and calibrator-Correction machine-Transmission line-Unload Platform;

One step diameter:25-426mm;

PPR/PE/PVC One step PU insulation production line

PE foaming Production Line applicable for solar tube and air-conditioning pipe

Corrugated PU insulation pipe production Line

Two step pre insulated pipe production line consist of:

Extruder-Die&Mould-Cooling Device-Haul off machine-Sealing machine-Stacker-Foaming Platform-Steel pipe threading machine-High pressure foaming machine

Two step: 550-1400mm

Two step insulation HDPE jacket machine specification:

Extruder | Haul-off machine | Die | Pipe range |

SJ-90 | SJGF-400-4 claws | Φ110-Φ250 | Φ75-Φ400 |

SJ-120 | SJGF-800-6 laws | Φ420 | Φ400-Φ760 |

SJ150 | SJGF-1500-8 claws | Φ760 | Φ600-Φ1400 |

Step 1: Produce the PE casing (straight PE jacket machine)

(Sprial Jacket Production Machine)

Step 2: Thread steel pipe inside PE casing

Step 3: Foaming table help foam inside the middle layer;

New Innovated Continously spray insulation foaming production line:

Spray PU foaming layer

![7dadf3551347155a3e79[00_00_08][20211210-160913](1)_副本](/res/en/20211210/auto_525.png)

Coating PE jacket by single screw extruder

![85be12d7fb710a38081e[00_00_02][20211210-161355]_副本](/res/en/20211210/auto_526.png)

Finshed Product

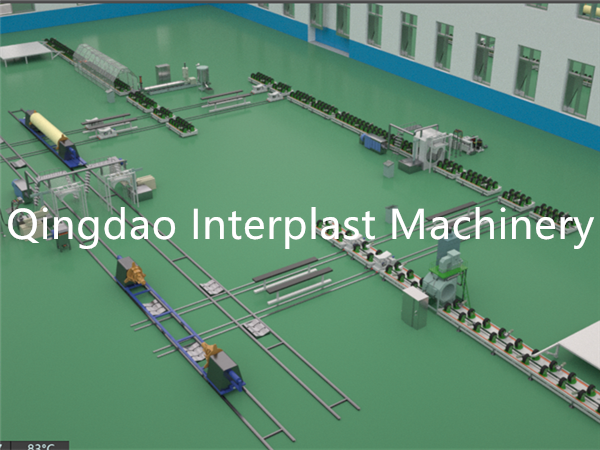

Layout of PU insulation production line

Send Message